High speed and efficiency, energy saving

Home Core Strengths Core Technologies

High Speed Permanent Magnet Motor Technology

The high speed permanent magnet synchronous motor developed by Shuo Yuan Power is optimally designed for high speed rotation to meet its needs of low current loss and continuous high speed operation, minimising high frequency loss, with an efficiency of up to 98%.

Streamlined motor construction for durable and stable operation in multiple operating conditions.

Optimised high speed rotational design up to 120,000RPM.

Smaller size, lighter weight, higher power density.

Start-up current of only 4.5% of the rated current, without the need for an additional start-up disk.

The impeller is directly connected to the rotor shaft and driven directly, completely eliminating mechanical transmission losses.

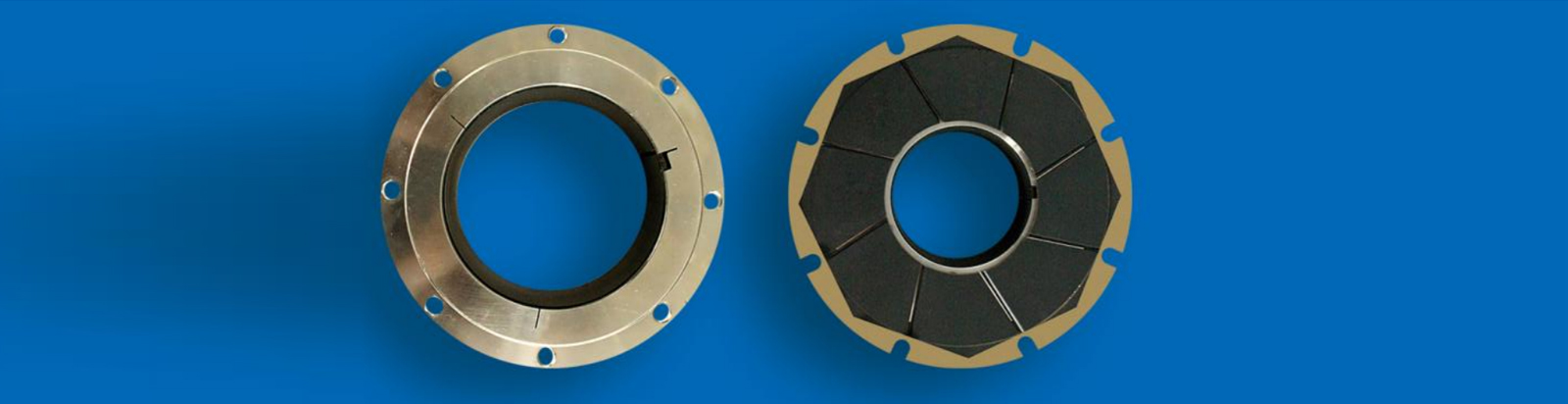

Air Dynamic Pressure Bearing Technology

Air dynamic pressure is naturally generated between the rotor and the foil structure bearing when the rotor rotates at high speed. Air dynamic pressure bearing is a non-contact bearing that uses air dynamic pressure to levitate the rotor. Air dynamic pressure bearings are widely used in ECS/ACM of aviation equipment and have high reliability.

100% oil-free using air as a lubricant, a clean and environmentally friendly component.

Non-contact bearing, zero friction in operation, no power loss.

Mature technology, simple construction, no grease lubrication system, no maintenance required.

Maximum speed up to 100,000 rpm, high working capacity at ultra-high speeds and good stability.

High load-bearing capacity, bearing structure to effectively suppress rotor vibration, small amplitude (<20μm), low noise.

Special coating technology to effectively reduce start-stop wear, enabling more than 20,000 starts and stops, with semi-permanent bearings.

Shuo Yuan air bearings, can be replaced on site, no need to return to the factory, worry-free use.

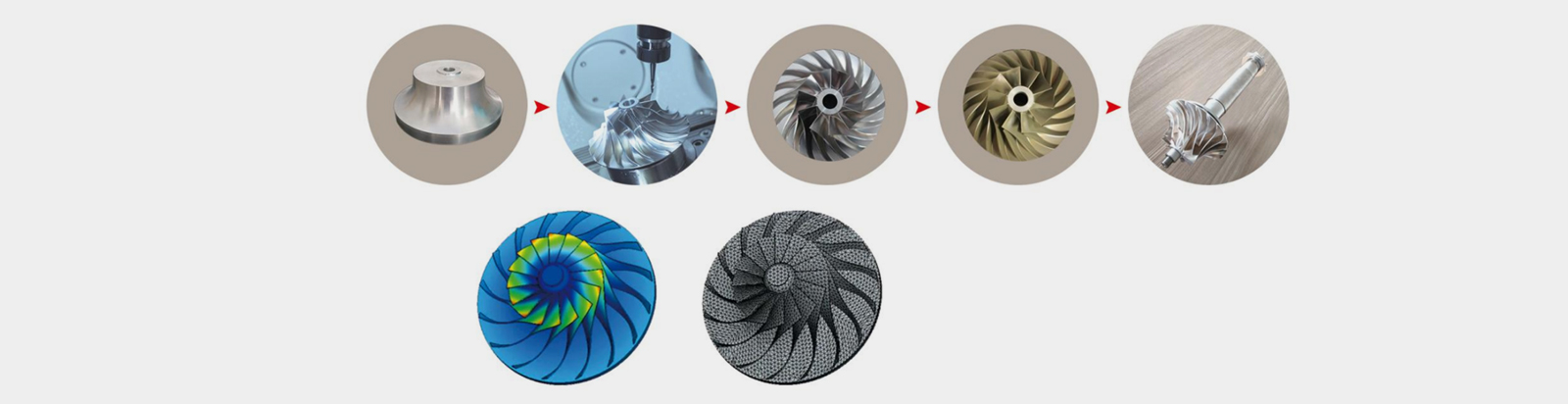

High Efficiency Fluid Impeller Technology

The Shuo Yuan high precision ternary flow impeller, relying on the most advanced aerodynamic design algorithms, uses aeronautical engineering technology to ensure that the impeller is lightweight and miniaturised while still achieving large air volumes and the highest efficiency in the industry.

Ternary flow backward curved precision design, matched to the optimum speed ratio to ensure maximum flow adjustment range.

Made of high-strength aircraft aluminium alloy AL7075, with 100% flaw detection of the raw material, robust and durable.

Five-axis CNC precision machining to ensure high pneumatic efficiency of the impeller.

Passing the 115% overspeed test to ensure safety and reliability over the life cycle.

Surface anodising to improve the durability and corrosion resistance of the impeller.

Directly connected to the motor shaft for maximum efficiency of the whole machine.

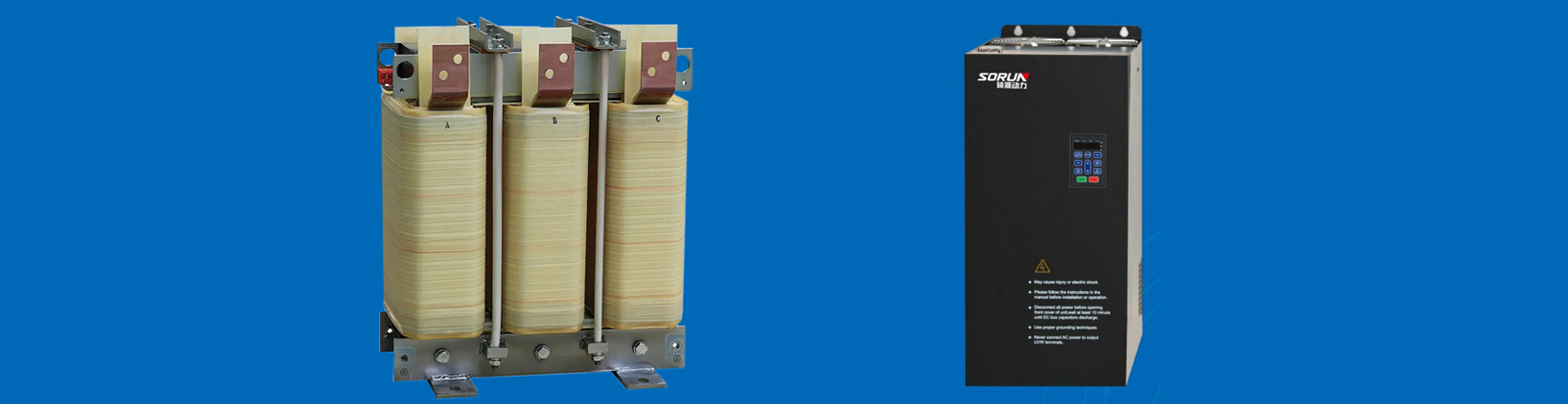

High Frequency Inverter Control Technology

Shuo Yuan air suspension centrifugal blower, using the most suitable for high-speed permanent magnet synchronous motor frequency conversion technology, non-inductive vector closed-loop control, to improve the operating efficiency and optimize the system performance of the fan.

The motor can be started with 100% frequency converter;

Precision operation with good adaptation of parameters.

High control performance with a control efficiency of over 96%.

Rapid response for timely response to load changes.

Built-in DC reactor for effective suppression of power harmonics;

A comprehensive range of protection features ensuring a very high level of stability and reliability.

Control of the motor speed by means of a frequency converter to regulate the blast flow and pressure required for the working conditions.

Save unnecessary energy consumption and achieve energy savings.

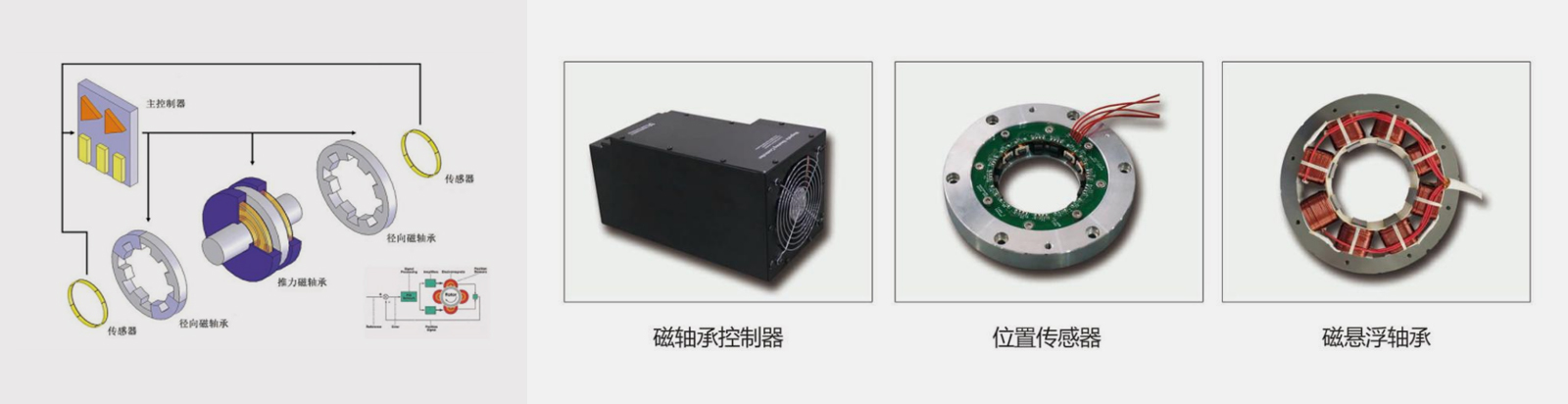

Active Magnetic Suspension Bearing Technology

The blower rotor is supported by two radial magnetic bearings and two bearing magnetic bearings and uses position sensors to monitor rotor position information and vibration signals. When the rotor vibrates or drifts due to changes in external forces, the controller restores the rotor to a stable state by adjusting the amount of current (magnetic force) controlling the magnetic bearing coils.Position sensor: Sensing technology with independent intellectual property rights for precise rotor position information in real time. Magnetic suspension bearing: Designed for the loads to be applied to the rotor and with optimised design fluxes etc. to make it suitable for high speed systems. Magnetic bearing controller: The development of separate boards for PC-based DSP boards and electronic components such as power amplifiers provides economy and safety suitable for centrifugal machinery.

Wind Turbine Integration-related Technologies

Low noise, low vibration

Unique sound-deadening and vibration-damping chassis design.

Benefits from the non-contact air suspension bearing construction feature.

Low noise to below 85dB(A).

Low vibration to below 1mm/s.

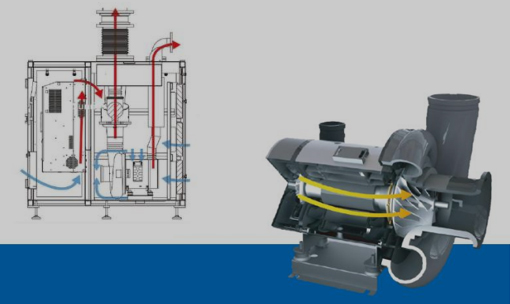

Versatile cooling system

Water cooling system: A unique internal circulation water cooling system for optimum cooling.

Air-cooling system: The perfect self-priming cooling system, which makes full use of the intake air to cool the motor and inverter without the aid of other equipment.

The heat generated inside the equipment can be optionally not discharged outside the enclosure to maintain a more suitable operating environment and equipment operation.

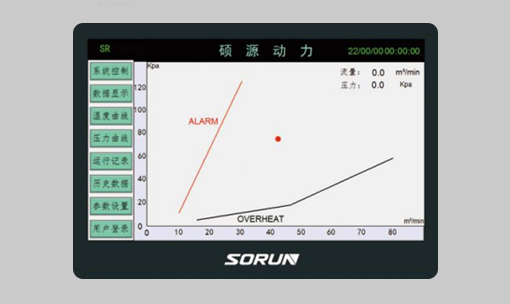

Surge protection system

The possibility of surging during plant operation is effectively reduced by the control of the surge prevention logic.

Easy installation

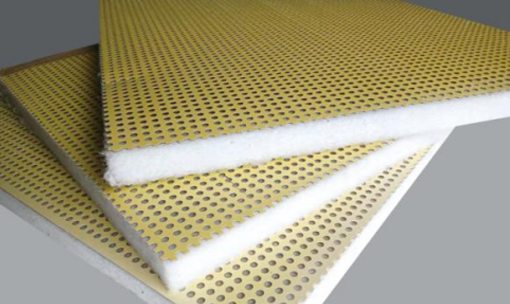

Only the filters need to be changed periodically and no other parts need to be replaced.

Improving the quality of the air delivered through the use of filter pads.

Achieving minimum equipment management time.

Long-term low maintenance costs.

Easy installation

All-in-one integrated equipment for plug-and-play.

No anchors are required, the equipment is prevented from being installed in the required position and the installation is completed by connecting the pipes and power supply.

The regular shape of the equipment and the small installation area.

Horizontal feet adjustable under the equipment for easy levelling and installation.

Significant reduction in costs for construction, foundations, cabling, pipework etc.

Humanised control system

High stability for precise fan control.

Easy control of the required operating points and real-time knowledge and diagnosis of the plant's operating conditions through Siemens PLCs and touchscreens.

Support for various control modes such as constant speed/pressure/constant flow.

IoT as standard, enabling remote control and control of equipment operation at any time and from anywhere.

Self-protection settings, each parameter can be set to a limit value, exceeding the limit can be set to prompt, alarm, automatic stop.

The touch screen interface is friendly, the data information is comprehensive and the operation is intuitive and simple.

| All | Products | Quantity | Operate |

|---|

Online Message